using APPS

WAREHOUSE &

SHIPMENTS

Business Central expert

This is #5 of 8 articles about how to cover your entire business with BUSINESS CENTRAL

– without customer extensions

– only using APPS

Fulfill all your needs for managing WAREHOUSE and SHIPMENTS in BUSINESS CENTRAL.

In this article, we explain what you should require, how you avoid customizations, and which APPS to use.

Warehouse Management is basically about managing the processes in the warehouse. In general, inventory management in ERP is about managing items, variants, quantities, and locations, and when we introduce Warehouse Management, it is also about Shipping and Receiving documents and bins.

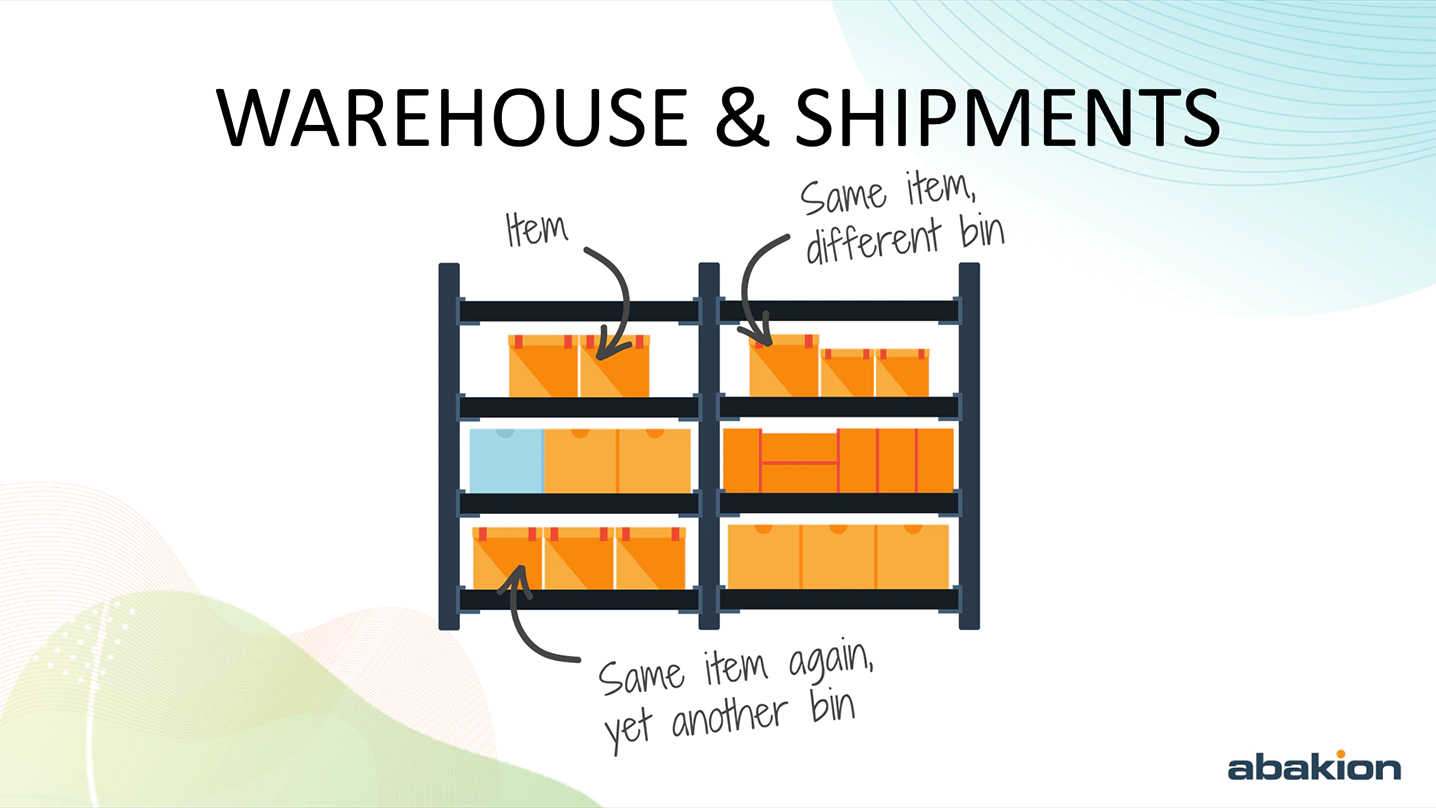

Normally we just know that we have 10 items in stock, but with Warehouse Management we know that there are 4 items on shelf A and 6 items on shelf B.

» Objectives for WMS

It is important to know the difference between a location and a bin in Business Central. A location is of a geographical place like a fabric or plant. The specific location is divided into many bins.

The impressive thing about adopting a Warehouse Management solution is how quickly everything falls into place. We regularly meet companies that want to introduce a warehouse solution, coming from a situation without bins. Once they get going with it, the system keeps track of everything.

We just need to sort out the terminology, because inventory management means several things in the ERP world.

LEVEL 1: FINANCIAL INVENTORY MANAGEMENT

Keeping track of the quantity and value of each item is the traditional financial and quantitative way of looking at inventory management. It is the foundation for the ability to keep track of the items in our ERP system. It allows us to purchase an item and put it away in inventory, and we can also sell it and withdraw it from stock.

LEVEL 2: INVENTORY MANAGEMENT WITH BINS

With a Warehouse Management System – items per bin enter the picture. As well as knowing the quantity, the system also keeps track of which bins an item is placed in. There may be twelve units on one shelf and three on another; each time we move the item – physically – we must tell the ERP system straight away, so everything stays under control. A whole new level of registration is required, which requires a scanner solution.

» Registration Solution

Internal warehouse processes

We have a receiving zone, a picking zone, a shipping zone and a backend zone. When a truck arrives, we quickly get the goods into the receiving zone and get them registered, but we don’t have time right now to put them away yet. Then we need clever logic that can help with where the goods should be put.

We place entire pallets in the backend zone, and then we replenish the picking zone, where we take from the backend and move out into the picking zone. It may also be that we move goods from the high storage to the picking zone.

We must be able to carry out stock counts and regulate the stock. If goods are missing or broken, we must reduce the stock. Warehouse Management requires counting per bin, and this is a job we need to be able to do with a scanner.

When the goods must be shipped, we prepare a warehouse shipment and pick the goods for shipment.

Shipments – external processes

Shipments is about managing the part of the shipment that takes place outside the warehouse. We have receipts that arrive at the warehouse and shipments that leave the warehouse.

We must manage what items we expect to receive and plan how we will send items to customers. We must manage waybills and freight forwarders.

If it is a whole container of goods that we receive in the warehouse, then we would like to have tools to receive the goods in an easy way. We need to know which items should be in the container and we need to be able to verify that we have received what we expect.

Pick and shipment

The items can be picked for sales orders or for production orders. We create a pick so employees can pick the goods in the warehouse, and in the packing zone we will pack the goods in the optimal boxes and send them with the forwarder.

We have to keep track of the number, volume and weight, and we have to print labels for the boxes. It is in this process that we switch from focusing on goods and quantity – to boxes that must be shipped, and we have to keep track of what all the boxes contain.

We need to be able to schedule shipments to have freight forwarders come at different times and pick up shipments, and we need to be able to schedule picking and packing to match shipments. Once we have picked and packed goods, they should be placed in the shipping zone in the order in which they are picked up by the forwarder.

Picking is probably the biggest mathematical challenge. We must pick the orders where we have all items in stock. The sales orders must be prioritized, both in relation to the customers and in relation to the shipment, and at the same time we must plan an efficient route in the warehouse for picking, and we must calculate which boxes the goods must be packed in.

Often the items are picked on a trolley, but the smartest is to pick directly into the box. This assumes that Business Central can tell which size box the picker must choose.

3PL and consignment warehouse

We can also have stock placed elsewhere, for example at dealers who have goods on consignment, so when we want to replenish their stock, we must be able to do so with transfer orders.

It can also be in a warehouse hotel, which is responsible for our warehouse management and dispatch of our goods to customers. It requires a lot of integration.

OBJECTIVES FOR WMS

We have four benefits that we want to achieve with Warehouse Management, and they are:

- Financial predictability

- Higher service level

- Minimized inventory binding

- Optimized picking

If you don’t already have a warehouse solution, you should prepare thoroughly. For example, you should look at the following:

- how big your warehouse is

- how many picks you have

- the type of picks you need

- whether you want to pick for several customers at once

- whether or not you want to pick for a customer across sales orders

- whether you want to manage the volume and dimensions of items

- whether you want the ability to pick items in different units of measure

- whether items come in packs with differing quantities, and whether they have different markings and IDs

- whether you have odd-size picks, such as a 2-metre-long broom that cannot go in a cardboard box

- whether you have barcodes everywhere they are needed

There is a lot of work involved in moving from paper to an IT warehouse management solution. Let’s go through the four advantages that we should make sure we obtain when introducing a warehouse solution.

Advantage 1: Financial predictability

The first advantage is that our inventory is always correct – in contrast, that is, to the traditional model where we have to carry out an inventory counting several times a year, requiring us to block out several days on the calendar to tot up all our goods… only to find a very high discrepancy.

With a warehouse solution, it is easier to keep stock constantly updated so that we never build up a big discrepancy.

The great thing is, this is an advantage that appears of its own accord. When we go to pick an item and it isn’t there, we simply register an adjustment. This way, counting goes on continually on a per-bin basis, rather than periodically per item.

The first advantage, then, is financial predictability.

In the traditional situation, where we count the stock several times per year, everyone holds their breath for several days as we do the count, because nobody knows whether the discrepancy will turn out positive or negative.

How big are the inventory discrepancies currently? And what is the target with the introduction of a warehouse solution?

If we are suddenly landed with a difference in the millions, it will have a direct impact on operating profit and give rise to some worried expressions in the finance department.

Advantage 2: Higher service level

When the inventory is more accurate, it also becomes easier to raise the service level and Perfect Order Fulfilment rate we provide to customers.

If an item is broken, we can scrap it straight away. When something isn’t right, we can adjust it straight away instead of waiting for a count.

Perfect Order Fulfilment is about how many sales orders we deliver to customers perfectly, by the agreed time, at the agreed price and without complaints. Of course, we want our customers to be happy – and they will be, if they get what they want, when they want it. That is the epitome of a high service level.

It is actually not enough to deliver at the confirmed time. If you go by SCOR (Supply Chain Operations Reference), the ‘true’ service level should be measured against what customers want to get. If we can deliver that, we are good at what we do.

If our service level is too low, we are probably looking at goods that we have trouble obtaining in time, because planning is insufficiently rigorous or because we have a short outbound delivery time and a long inbound supply time, if we are purchasing goods in China, say, and delivery takes 6 months, but the customer expects to be able to buy the item at a day’s notice.

So, we have a challenge. In this situation, we need to have our planning firmly under control.

However… in addition to this traditional challenge, we also need to think about inventory management.

If we think the item is in stock and sell it, but the stock turns out to be empty, we have a major challenge on our hands.

To attain a good service level, it is essential that the inventory adds up. This is why we need inventory management with real-time updating.

Advantage 3: Minimized inventory binding

At the same time, a warehouse solution enables us to reduce the amount of capital tied up in inventory.

It is an eternal question of priorities: whether to raise the service level by increasing stock levels or minimize tied-up capital and live with a lower service level or higher reordering costs.

Detailed inventory management gives us more chance of having our way on both fronts.

If our inventory management is in a mess and we cannot be certain whether there are discrepancies in our stock, we need to purchase bigger quantities so as to be sure of having enough in stock – thus increasing liquidity tie-up.

When we can manage the inventory with more precision, we can purchase more astutely and thus reduce inventory value without it affecting the service level.

Advantage 4: Optimized picking

One of the things companies pay most attention to when introducing a warehouse solution is sales order picking – the ability to pick in the warehouse and to be guided around the warehouse in an optimal picking route. An optimal pick is all about the shortest, smartest route possible.

There are many different pick structuring models. We therefore need to be clear which demands the ERP solution will take into account when organizing picks. There are usually many different scenarios to consider.

If we have a great many sales orders, many of them for the same customer – for example, if we supply a large retail chain and have ten different open sales orders for them, of which some are backorders, some are for tomorrow and some were for yesterday, the inventory solution should intelligently put together a pick across the sales orders.

Perhaps we want to do a ‘bulk pick’, picking for 20 different sales orders to different customers all at once, because they are relatively small orders; when we arrive at the dispatch area, we separate the items and put them in boxes. This is called ‘bulk pick’.

It may also be that we want to work with ‘box picks’, where we pick directly into the shipping pack. If we have to pick for four sales orders, the inventory solution will ask us to pick into four different boxes.

The system must keep track of volume and needs to have worked out in advance how big those boxes have to be. This saves us from having to repack the items in the dispatch area, because we have picked straight from the shelf into the shipping pack. This is called a ‘box pick’ or ‘pallet pick’ according to the type of pack involved.

In addition, we may want to pick everything bound for abroad before 9 am, because that is when the carrier comes to collect consignments for abroad. The inventory solution must therefore be sure to organize the picks so that we aren’t picking all the orders for local addresses, which then take up space in the loading bay, when the lorry bound for abroad arrives.

When it comes to picking, there are many different demands that are crucial to our ability to optimize the warehouse. Of course, the picker needn’t worry about all this. The hand terminal should just guide the picker along the best route.

‘Take a trolley with two boxes, sizes 3 and 5. Pick the items on this route.’ The system should organize all this for the picker.

When an order has been picked, the warehouse solution should create the shipping documents and integrate with the carriers.

The important thing is for the solution to take care of booking the carrier to come and of passing on all necessary data so that no manual processing is required.

REGISTRATION SOLUTION

Some companies can do without scanner terminals, but only because they have a small warehouse and work with fixed bins.

The first paradigm in a warehouse solution, then, is that we must register everything that happens in the warehouse; in practice this is often only feasible with a scanner registration solution.

Most companies need devices to carry out registrations in the warehouse. These may be expensive hand terminals, truck scanners or just smartphones running a mobile version of the Business Central ERP system.

If we have a small warehouse, this can be done quite simply, straight from a mobile client into Business Central. But some form of registration solution is a must.

Online or offline

And the first decision to be made on this is whether we will work online in the ERP system, or offline. In other words, whether we want our registrations to be updated in the ERP system without delay (online) or in batch mode (offline).

If everything is updated online in the ERP system, a salesperson can create a sales order that will straight away be sent to the warehouse, where the order can be picked immediately.

In many warehouse solutions, picks are generated in the morning, when a batch job in the system works out how much we should pick in the course of the day; it then creates all the picks, and we get a job sheet showing what we have to do today.

More recent systems create one pick at a time. When the picker is free or has finished picking, he presses a button on his terminal to get details of the next pick, whereupon the system creates the next pick for him. This means that, if a new top-priority sales order has just come in, it will be the next one to be picked.

It can also happen that items have come into arrivals just a moment ago, and the system can now see that this item is available and start allowing it to be included in picks. The debate about whether registration should take place online or offline is very important. Real-time planning of picks has some advantages, of course, but that does not mean it is always the best solution.

For example, we must consider how good our network coverage is. Online naturally requires uninterrupted internet access. Access points are usually set up throughout the warehouse, and this is easy as long as we are in an ordinary indoor warehouse.

We normally recommend working online as much as possible, but if we do not have uninterrupted internet coverage, we will have to work offline.

Equipment

The choices discussed above may determine the type of hand terminal equipment we need, but otherwise:

If we have a lot of picks and a lot of pickers in a large warehouse, there is usually a good business case for choosing proper scanner terminals with lots of features – ones that can withstand non-stop use and being run over by a forklift.

If we have a relatively small warehouse and just want to carry out occasional registrations, we may be able to make do with a tablet or mobile phone directly connected to the ERP system. These are much cheaper but also significantly more fragile.

Volume is what mainly determines the choice of equipment.

PACKS, BAR CODES AND BREAK-BULK

Let’s drill down into some of the feature requirements that often pose challenges in a new warehouse solution.

Packs

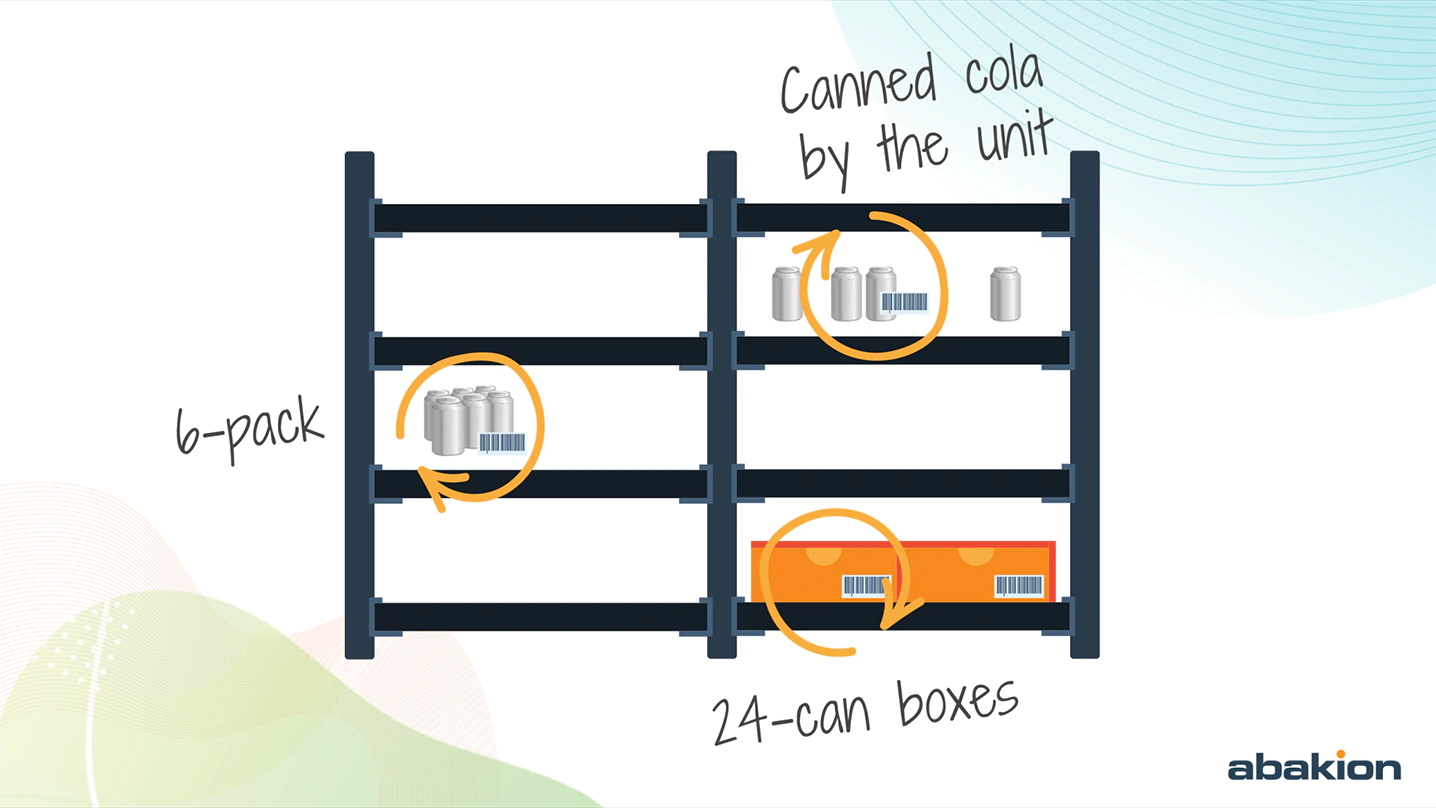

We sell an item, such as a cola, by the unit, and there is a barcode on each can of cola, but they are packed 6 to a pack.

Should we therefore have a different barcode on the outside of the pack, or should it be the same barcode – in which case, will we need to remember to register 6 units when we scan a pack?

If the packs of 6 are packed into a box containing 24 in total, does that box have a new barcode as well?

Now, if there are different barcodes on the cola, and the system can recognize the quantity, the same principle then applies to all other items. Otherwise, mispicks are bound to occur. If we are to manage this challenge well in the ERP system, the system must support an item structure with packs in a variety of quantities.

Otherwise, it will be awkward to manage – either in the item structure of the ERP system, or in the scanning situation in the warehouse. We must keep good track of the packs and quantities we are picking in.

Barcodes

When we introduce a new warehouse solution, the most time-consuming aspects include putting the barcodes into our ERP system, setting up the bins and attaching labels to all the shelves in the warehouse where we want to use hand terminals for scanning.

It does not have much to do with the ERP solution itself; it is a low-tech job that has to be done. Unfortunately, there are many companies that do not have barcodes on all their items and all their bits and pieces.

For example, if we are a food company and we purchase a batch of cauliflower, it won’t be delivered with a barcode on each head of cauliflower. So how do we register them? Must we keep the code for a cauliflower in our head, or do we have to walk over to a board somewhere and leaf through to the picture of a cauliflower so that we can scan a barcode?

This problem is not confined to the food industry. Barcode scanning is a challenge in many sectors.

Alternative non-linear units of measure

There is another major challenge for ERP systems in the warehouse: different units of measure. Most ERP systems handle unit codes perfectly well. We stock canned cola by the unit, but we also have it in a 6-pack and a 24-pack.

We deal with this by creating relationships between unit codes in the ERP system. So, we have units, packs, frames, boxes, collis and so on. Most ERP systems deal with this nicely.

The hard part is non-linear units of measure.

A classic example might be frozen chickens. We sell frozen chickens in boxes of 20. There are 20 to a box when we purchase them, too, but settlement of accounts, both for sales and for purchases, is by real weight.

We order a pallet, which is 40 boxes, from our vendor. Then they arrive; we register receipt of 40 boxes on the purchase line in the ERP system, and it works out for itself that this makes 800 units.

In practice, however, when we scan them in at the warehouse, we may scan each box separately and record the weight, which may turn out to be fewer kilos than the purchaser thought. Chickens can vary a lot in weight, and we want to manage this in ERP as well.

Ultimately, everything has to be settled up according to weight, so the ERP system must keep track of multiple non-linear units of measure for the same item. We refer to this as alternative unit codes, or ‘second unit of measure’ in ERP terminology.

If we import hams from Italy and purchase them in quantity, there can be wide variations. The hams weigh between 1.2 and 3.5 kilos each. Our customer orders 3 hams and gets 3 delivered, but payment must be by weight. In this situation, it is crucial that our ERP system keeps track of the units.

As a rule, the challenge for the ERP system is not that the units of measure change between purchase and sale. That is fairly easy to handle provided the units of measure are linear, with 1 kg being equivalent to, say, 8 units.

The ERP system will work with a base unit, typically the one used for stocktaking and the one the items are stocked in, financially speaking. Although we purchase 100 kg, the system will stock it in terms of the base unit, as a quantity of 800.

When the relationship is non-linear, though, there is not always a natural base unit, and things start to get difficult in the ERP system.

It is not much fun having 100 metres of planks in stock if they are all only 20 cm long because they are offcuts from timber sawn to length for customers. What unit will we count planks in if we need to do an inventory counting? ‘Several’ is probably the best answer.

ERP wise, a separate entry type system is required to manage the various unit codes behind the scenes.

We don’t want this custom-developed in our ERP system, as that is a major undertaking. We want the warehouse management solution to handle it.

Breakbulk

Perhaps we also need to manage breakbulk in the warehouse. We can see that we have 10,000 cans of cola in stock, but perhaps we cannot see what breakbulk they are in. How many are packed in 6-packs or in boxes of 24?

In the hams example above, a customer might order 3 hams, each to be at least 2.8 kilos. Should our system be able to tell us whether we can deliver? It may well be that we can deliver 3 units, and that we can also deliver 8.4 kilos, but that doesn’t necessarily mean we can deliver 3 units of at least 2.8 kilos each.

If we run a timber yard and buy planks in fixed lengths, how many details must the ERP system keep track of? Perhaps we can see that we have 400 metres in stock, divided into 200 planks, but not what lengths they are.

If a customer orders 100 3-metre planks, we may have enough in stock in terms of both length and quantity, but, if a lot of them are cut up into small pieces, we are not guaranteed to have 100 3-metre lengths.

If we want to know what planks we can actually pick, the ERP system must have both breakbulk and unit codes firmly under control.

ITEM TRACKING

Item tracking – either expiration date management or ordinary lot or serial number management – is a classic issue. Business Central must support it elegantly (and yes, there are many inelegant ways of managing it).

There are many industries in which item tracking is now either relevant or a definite requirement.

Lot numbers and serial numbers

Essentially, there is lot number tracking (also called batch number tracking), and there is serial number tracking.

The difference is that the serial number is unique to the unit. It is always a quantity of 1 unit that has a unique serial number. Serial numbers are very common in the electronics industry, for example.

Lot numbers are used when an item is produced in a batch, and all units in that batch receive a lot number so that they can be recognized. This can apply to liquid products that can be drawn off, or to ordinary goods that can be picked. It can certainly apply to items that are produced in quantity but receive a lot number because they are produced in batches.

For example, you might have 5,000 trays of pâté produced in one go and therefore given the same lot number. Or a cubic metre of plastic widgets etc.

One of the criteria for choosing serial number management is that the serial number must be on the individual item. Otherwise, it makes no sense.

There are also some industries that put both lot numbers and serial numbers on the same item, to show that a particular serial number was produced in a particular batch production.

Business Central knows how to manage lot and serial numbers. Once an item has been set up to show whether it has a lot or serial number, Business Central manages it nicely all through the hierarchy.

If we are going to produce those 5,000 trays of pâté, for example, and we purchase meat and milk, in receipts we register a lot number on the purchased items.

And, if we do not receive a lot number from the vendor, we can create our own, consisting of a date and an ID number. This way, we know when the individual raw material was received, and from which vendor.

Each time we handle the raw materials in the warehouse, we indicate the lot number on the items you take. When the raw materials are included in a production of a finished product or perhaps a semi-finished product, we register the lot numbers included, and the result of the production order is allocated a new, trackable lot number.

A tray of pâté thus ends up as a hierarchy of lot numbers, enabling us to drill down through the hierarchy and track all the raw materials included in a specific tray of pâté.

If we identify a raw material that is a problem, we can navigate up through the hierarchy and trace all the finished products that include the problematic raw material lot number.

This is traditional item tracking, something the ERP system can support very straightforwardly.

Clearly, item tracking demands more registrations in the warehouse and in production, but we should ensure that the structure in the ERP system does not add to the difficulty. We should always be able to ‘scan our way out’. We should minimize manual registrations.

No manual entering

Normally, we will either have the lot number on our raw materials or print labels with the lot number on when we produce the item.

So, for example, if we produce an item to which the system automatically allocates a lot number, the system must be able to print it out so that it appears on a label with a barcode and thus can easily be scanned.

Nothing should have to be keyed in manually. We should be able to manage the item purely by means of the scanner terminal. This can be set up in most warehouse solutions.

We may well have some items that are tracked and others that are not. The milk and meat for the pâté are tracked by lot number, but salt and pepper may not be. Most systems can handle this.

EXPIRATION DATE MANAGEMENT

Expiration date management

Challenges usually arise in Business Central when it comes to expiration date management. When we purchase an item, it will say on it when it expires, and we must be able to register this in the ERP system.

And, when we produce an item, we must be able to select an expiration date formula on the item card so that the system calculates a date, e.g. 1 year from the date of production, and stamps that specific expiration date in the system.

This in itself is reasonably simple for most ERP systems

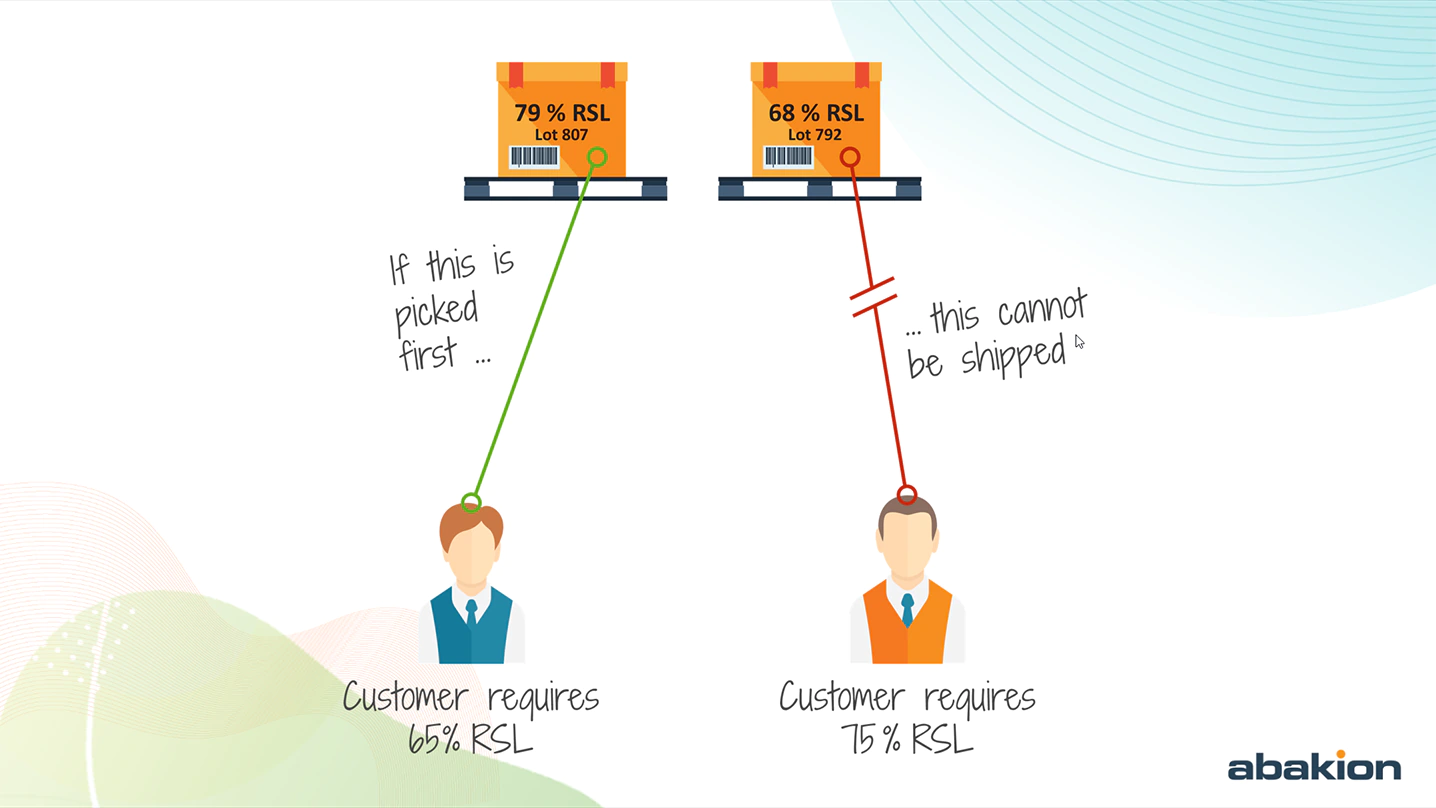

Things get a bit trickier when we consider “remaining shelf life” (RSL).

Remaining shelf life

When our customer buys the item that expires 1 year after the date of production, the customer may set a requirement for the amount of shelf life remaining. When the item reaches the supermarket shelf, the supermarket may require the remaining shelf life to be at least 75%.

The remaining shelf-life requirement is not always expressed in days; it may be a percentage of the item’s total shelf life.

Our customers will normally have different remaining shelf-life requirements, and it can be very difficult to manage this and make the ERP system take it into consideration when calculating inventory picks.

For a start, the pick algorithm should be smart enough to pick items for the customers with the least restrictive requirements, so that they receive the oldest items. This way, we can be sure of being able to meet the remaining shelf-life requirements on as many orders as possible.

Our customers may also make things a little more complex by stipulating “single batch”, meaning that the customer insists on the whole shipment having the same lot number, or “single-layer batch”, where all layers in a pallet must have the same lot number.

Many customers set requirements of this sort because they do not want to scan many different lot numbers, with different quantities, in their arrivals area.

“Single batch” makes it much easier for the customer – but more complex for our ERP system.

If we have a customer who places a big order with a “single batch” requirement, the ERP system will probably have to pick for this customer first in order to be sure of being able to deliver. But this can cause conflicts.

If another customer only demands 50% remaining shelf life, we really want to pick for this customer first, because then we can take the oldest item. If this pick splits a batch, though, we may not be able to deliver the big ‘single batch’ order at all.

In reality, we therefore often need to consider those with the most restrictive “single order” requirements first and consider remaining shelf life afterwards.

This soon becomes a mathematical exercise where the ERP system must juggle all the requirements and combine items so that as many orders as possible get picked.

If nothing else, this requires the inventory to be 100% correct.

And it requires a Warehouse Management solution that is good at planning picks according to all the criteria that customers set.