Manage Sales Orders to avoid partial deliveries and shortages using Shortage on Demand Orders

Shortage on Demand Orders is an app for Microsoft Dynamics 365 Business Central that helps you make intelligent decisions about which Sales Orders to prioritize when item shortages occur. This is a planning tool for companies wanting to optimize fulfillment of Sales Orders to avoid partial deliveries by moving delivery dates and not necessarily serving customers in the order they came.

Gain insight on shortages

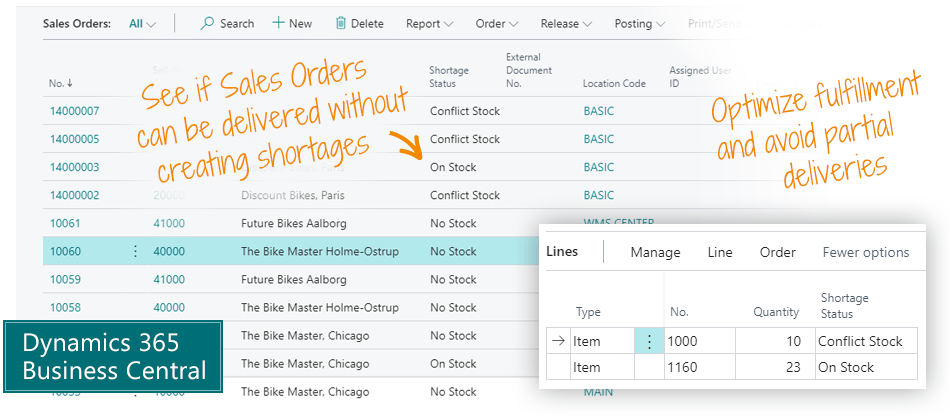

Shortage on Demand Orders provides an overview of which Sales Orders you can fulfill completely or partially – or not at all. It helps you evaluate which orders you want to pick and ship.

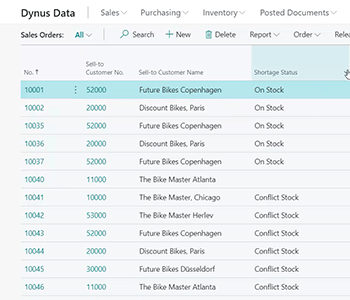

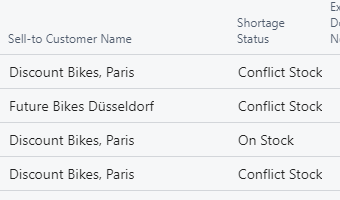

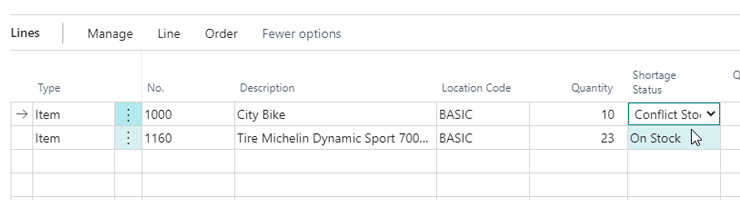

On the Sales Order List and on each Sales Order Line, you get a status code that shows the inventory availability. Search for all Sales Orders with the status ‘On Stock’, and you know that you can deliver them all without worrying about shortages.

The ‘Conflict Stock’ status tells you, that fulfillment is possible but will cause a shortage on another Sales Order. This way, 8 different status code provides actionable insight for picking the right Sales Orders to deliver.

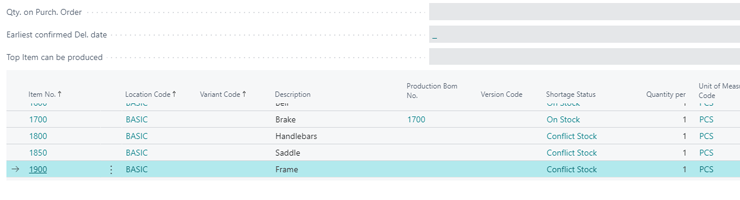

Shortage on Demand Orders also works for Production Orders, in which case the calculation is based on Component Shortage.

Main Benefits of Shortage on Demand Orders

For Warehouse Management:

- See which Sales Orders can be released to pick, knowing they can be picked completely.

- See shortages on items from the top level and all the way down through the hierarchy.

- Start the day by picking all the Sales Orders that can be delivered completely. Then proceed with orders that can be delivered but cause shortages on other orders – and only then move on to partial deliveries.

For Sales:

- Reduce the number of partial deliveries and partial invoices by helping the warehouse prioritize which sales orders you want delivered.

- The ability to promise clients that their order can be delivered without any problems, or to assess whether the order causes a conflict.

- Fewer shortage situations make happier customers.

For Finance:

- Lower delivery costs when the number of partial deliveries is reduced.

- Happier clients because you can keep your order promises.

- Less frustration in the warehouse because picking becomes simpler.

Abakion is your one-stop shop for Apps

Book a Q&A-session about the app

If you have questions about the app – after watching the video with the demonstration – you can sign up for a free Q&A-session with one of our experts. You can ask any question you may have.

STEP 1: Watch the demos

First, please watch the videos with the demonstration of the app:

STEP 2: Book a meeting

Pick a date in the list – and book it in your calendar.

| Dato | Kursus | Book now |

|---|---|---|

| 31JUL | Personal Q&A-session. In English. You will receive presentation videos to prepare for this Q&A-session. | Book now |

| 31JUL | Personal Q&A-session. In English. You will receive presentation videos to prepare for this Q&A-session. | Book now |

The features of Shortage on Demand Orders

Shortages on Sales Orders

See which Sales Orders can be delivered without creating backlogs.

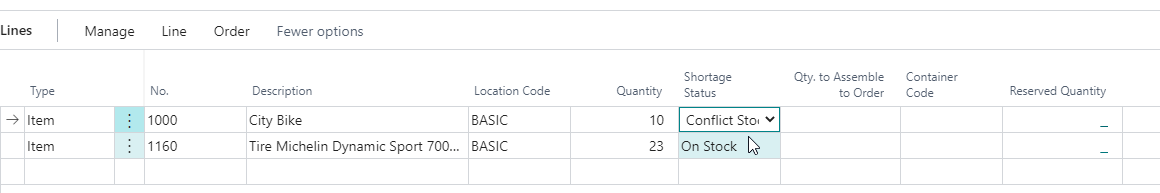

Shortages are calculated bottom-up

The Shortage Status is calculated for each Sales Order line, and the “worst” Shortage Status is transferred to the Sales Header. This way you can easily see if the order can be shipped completely, or you can see which Sales Order Lines that causes the backlogs.

Shortage status codes

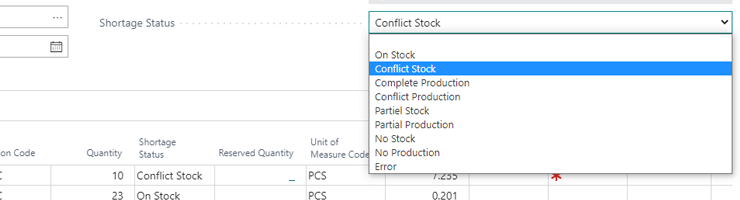

You have 8 status codes and 1 error message available. The many levels of shortage status provides you an actionable insight into the exact status of item and component availability.

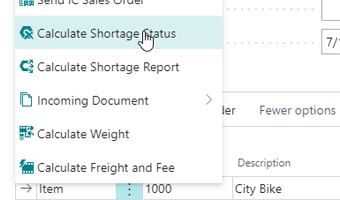

Calculate shortage on a Sales Order

You can activate an update of the Shortage Status on a single Sales Order. Then you have up-to-date information.

The way to understand the different statuses of Shortage on Demand Orders

| (Blank) | No Shortage is calculated or the Outstanding Quantity on the line is blank. |

| On Stock | There are enough items on stock to cover all demands within the period selected. |

| Conflict Stock | There are enough items on stock within the period to cover the demand on the line, but not to cover all Sales Order demands for the item. |

| Complete Production | There are not enough items on stock to cover the demand. But there are components enough to create a Production Order and produce the item. And none of the components will conflict and run out of stock on other demands. |

| Conflict Production | There are not enough items on stock to cover the demand. But there are components enough to create a Production Order and produce the item. But there are not components enough to cover all demands for the components. |

| Partial Stock | There are not enough items on stock to cover the demand, and not components enough to produce the full demand on the line. But some items are on stock, and the demand can be partially supplied. |

| Partial Production | There are no items on stock, but components to produce part of the demand on the line, but not the full quantity. |

| No Stock | There is none of this item on stock at all. |

| No Production | There is none of this item on stock at all. And if it is a produced item, there are no components to produce a single item. |

| Error | Error on the calculation. For example, Production Bill of material lines that are not certified, Production calendar that is not calculated, etc. |

Drill down the Production hierarchy

If you use Production, it is possible to drill down through the complete hierarchy to figure out which components on lower levels result in problems on a Sales Order Line.

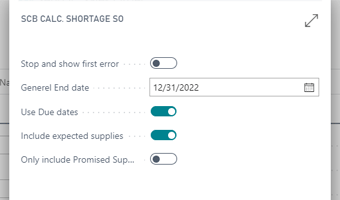

Bulk update all shortage statuses

Initiate a calculation of shortages throughout all Sales Order. Customize the filters and settings for the calculation. A similar process is available for Production Orders.

Getting started with the app

Download and install now

Read the step-by-step guide

Watch user guide videos

Shortage on Demand Orders pricing

Single app

Single user is DKK 120,00.

The more users you subscribe to, the cheaper each becomes. Watch video about the price model »

As part of the App Bundle

Talk to a real human

Have a chat with our app managers Bo H. Hansen and Thomas Halse about pricing and subscriptions:

appsales@abakion.com

We will reply in English.

Support

If you have specific questions about functionality or how to get started, you may contact our support team at frontdesk@abakion.com or call us at +45 70 23 23 17. We will help you find the right video guides, if available.

We strive to provide you a qualified response as quickly as possible, at least within 24 hours but often much quicker.

At all times we will keep you informed about who is working on your support inquiry and how soon you can expect a response.